Uncovering the Perks and Practical Use Aluminum Castings in Today's Market

Light weight aluminum castings have ended up being progressively relevant in different markets as a result of their distinct qualities. Their lightweight nature and resistance to corrosion make them ideal for requiring applications. Additionally, the remarkable strength-to-weight ratio provides considerable benefits in layout and manufacturing. As industries remain to explore their possibility, the full scope of aluminum spreadings' applications and advantages remains to be fully discovered. What lies ahead for this functional material?

The Lightweight Advantage of Light Weight Aluminum Castings

Numerous materials are made use of in production, aluminum castings stand out primarily due to their lightweight homes. This particular makes aluminum castings an attractive choice for numerous sectors, particularly in aerospace and automobile applications, where weight reduction is important for boosting fuel performance and performance. The light-weight nature of aluminum permits suppliers to create elements that are much easier to handle and set up, inevitably reducing labor costs.

Furthermore, the capacity to generate intricate forms without substantial weight fines makes it possible for developers to introduce while keeping architectural stability. Aluminum castings can efficiently change larger products, bring about substantial financial savings in delivery and functional costs. Their light-weight benefit additionally contributes to improved product long life, as lighter elements usually lead to lowered deterioration on machinery. Generally, the lightweight buildings of light weight aluminum castings provide makers with an affordable side, cultivating innovations in item layout and efficiency throughout numerous industries.

Phenomenal Deterioration Resistance

Aluminum castings have an all-natural resistance to oxidation, which significantly improves their durability in different settings. This fundamental home not just adds to their sturdiness yet also lines up with the lightweight benefit that aluminum offers. As an outcome, aluminum spreadings are increasingly identified for their remarkable corrosion resistance in numerous applications.

Naturally Resistant to Oxidation

Among the standout characteristics of aluminum spreadings is their extraordinary deterioration resistance, which originates from a natural oxidation procedure. When revealed to air, aluminum responds to develop a thin, safety layer of aluminum oxide. This layer functions as an obstacle versus additional oxidation and shields the underlying metal from corrosive elements such as wetness and salts. Unlike other metals, this oxide layer is self-repairing; if damaged, it rapidly reforms when revealed to air. This distinct residential or commercial property improves the longevity of aluminum spreadings in different settings, making them suitable for applications in markets such as aerospace, automotive, and marine. Consequently, the all-natural resistance to oxidation significantly minimizes upkeep prices and raises the reliability of light weight aluminum spreadings sought after conditions.

Lightweight Sturdiness Benefit

The lightweight nature of aluminum spreadings adds greatly to their toughness, making them a beneficial option in various sectors. This remarkable longevity is greatly attributed to aluminum's innate resistance to corrosion, which is boosted additionally with anodizing and various other surface treatments. Unlike lots of metals, aluminum does not rust; instead, it creates a protective oxide layer that guards it from ecological damage. This building is especially beneficial in fields such as automotive and aerospace, where weight reduction is crucial without endangering stamina. Furthermore, the longevity of aluminum castings decreases maintenance prices and replacements, providing economic benefits in time. Their lightweight toughness and corrosion resistance position aluminum castings as a remarkable product for modern-day manufacturing applications.

Superior Strength-to-Weight Ratio

An impressive attribute of light weight aluminum spreadings is their premium strength-to-weight ratio, that makes them extremely preferable in numerous applications. This intrinsic property enables aluminum spreadings to endure significant anxiety while continuing to be lightweight, an important factor in industries such as aerospace, vehicle, and production. Designers usually like light weight aluminum castings for components that require both resilience and decreased weight, boosting fuel effectiveness and efficiency.

The high strength-to-weight proportion also assists in the design of detailed forms and frameworks, making aluminum spreadings versatile for complex applications. The capacity to maintain architectural honesty under tough problems guarantees longevity and dependability in items, from airplane structures to automobile parts. This benefit contributes to the expanding pattern of making use of aluminum castings in ingenious layouts, inevitably resulting in enhanced functionality and effectiveness throughout varied markets. Subsequently, the premium strength-to-weight ratio of aluminum castings positions them as an essential material in contemporary engineering and manufacturing.

Cost-Effectiveness in Manufacturing

Cost-effectiveness in light weight aluminum casting production is mostly accomplished with decreased material waste and reliable production procedures. By enhancing styles and using advanced methods, producers can reduce excess material use while preserving quality criteria. This technique not only decreases production expenses but additionally adds to a lot more sustainable practices within the industry.

Lowered Material Waste

Reducing material waste in light weight aluminum spreading procedures greatly boosts production effectiveness. By enhancing the layout and manufacturing techniques, companies can reduce excess scrap and improve source utilization. This decrease in waste not only lowers product costs yet likewise adds to an extra lasting production design. The capability to reuse aluminum more supports cost-effectiveness, enabling manufacturers to redeem and recycle materials without jeopardizing high quality. As the market increasingly concentrates on sustainability, reduced material waste lines up with ecological goals while all at once increasing earnings. Inevitably, efficient use of basic materials strengthens the affordable position of organizations out there, making aluminum castings a favorable option in various applications. The calculated method to reducing waste reflects a commitment to both financial and eco-friendly responsibility.

Efficient Production Processes

While typical production procedures can incur substantial expenses, light weight aluminum casting provides a more efficient choice that boosts general manufacturing earnings. This approach reduces material waste and permits specific control over the manufacturing process, causing decreased labor and operational prices. The capability to generate complex shapes with less steps additionally streamlines production, adding to shorter preparations. Additionally, light weight aluminum's light-weight nature and excellent thermal conductivity permit for power savings during production and in the final application. By making use of modern casting modern technologies, suppliers can accomplish higher throughput without giving up top quality. Aluminum spreading stands out as an affordable remedy, making it an appealing alternative for services aiming to enhance their production procedures in today's competitive market.

Versatility Throughout Industries

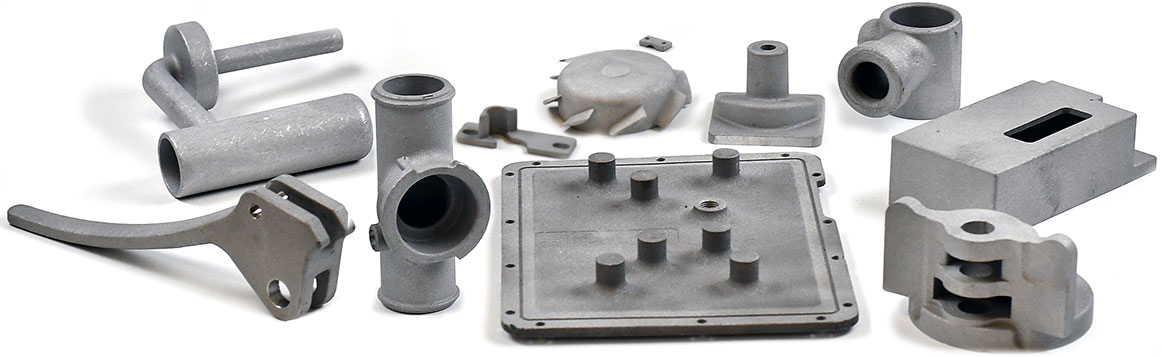

Light weight aluminum castings demonstrate exceptional versatility across various sectors, as they can be tailored to satisfy specific needs and applications. In the vehicle market, light weight aluminum spreadings are made use of in engine blocks, transmission real estates, and wheels, supplying light-weight yet resilient options that improve fuel performance. The aerospace market official site likewise takes advantage of light weight aluminum castings, using them in structural parts and engine parts because of their strength-to-weight ratio.

In the customer items market, producers use light weight aluminum spreadings for items varying from pots and pans to furnishings, supplying both aesthetic charm and performance. The electronics industry makes use of light weight aluminum castings for housings and warm sinks, ensuring reliable thermal management. Furthermore, the building and construction sector leverages aluminum spreadings for structural components and architectural aspects, enhancing longevity and design versatility. This wide applicability highlights light weight aluminum spreadings as a crucial resource, satisfying the varied needs of different markets while preserving high performance and reliability.

Sustainability and Environmental Influence

As sectors significantly focus on lasting practices, light weight aluminum castings emerge as a green selection due to their recyclability and low ecological impact. Aluminum is one of the most recycled products internationally, with the capacity to be repurposed several times without deterioration of top quality. This characteristic significantly decreases the demand for resources and power intake connected with primary aluminum manufacturing, which is energy-intensive.

In addition, aluminum castings add to lightweight designs, leading to fuel performance in transport applications such as aerospace and automobile industries. Their longevity and resistance to deterioration extend item lifespans, additionally lessening waste and source use gradually. Many producers are taking on accountable sourcing and environmentally pleasant production techniques, enhancing the sustainability of light weight aluminum casting processes. Generally, light weight aluminum castings represent a sensible remedy for services intending to reduce their environmental influence while attaining efficiency and performance.

Innovations in Aluminum Spreading Technologies

Current innovations in light weight aluminum spreading technologies have actually significantly improved the effectiveness and quality of manufacturing procedures. Developments such as 3D printing and advanced mold-making techniques have allowed producers to produce elaborate layouts with decreased material waste. This change not just boosts the precision of cast elements yet additionally shortens lead times, enabling fast prototyping and faster market access.

The consolidation of innovative computer simulations help in predicting possible issues during spreading, leading to higher-quality outputs. The use of light-weight alloys has actually additionally contributed to the advancement of more powerful, much more sturdy items, satisfying industries ranging from auto to aerospace

Furthermore, web automated spreading processes have actually arised, decreasing human error and enhancing manufacturing rate. Collectively, these developments are transforming the aluminum spreading landscape, driving better competition and sustainability in production. As markets continue to evolve, these innovations will certainly play an essential role in conference future demands for effectiveness and quality.

Often Asked Concerns

How Do Aluminum Castings Compare to Various Other Steels in Regards To Thermal Conductivity?

Light weight aluminum spreadings display superior thermal conductivity contrasted to many metals, such as steel and iron - Wisconsin Aluminum Foundry. Their lightweight nature and reliable warmth circulation make them excellent for applications calling for efficient thermal administration in numerous industries

What Are the Usual Defects Located in Light Weight Aluminum Castings?

Usual issues in aluminum spreadings consist of porosity, shrinkage, additions, and surface irregularities. discover here These problems frequently develop from inappropriate air conditioning rates, insufficient mold style, or contaminations, influencing the general high quality and performance of the final product.

Can Light Weight Aluminum Castings Be Recycled, and How?

Aluminum spreadings can be reused efficiently. The procedure entails accumulating, melting, and changing the light weight aluminum, which minimizes waste and preserves sources. This reusing adds to sustainability while keeping the product's properties for future use.

What Are the Typical Lead Times for Light Weight Aluminum Spreading Manufacturing?

Commonly, preparations for aluminum spreading manufacturing array from two to 6 weeks, depending upon factors such as intricacy, tooling demands, and manufacturing quantity. Efficiency can boost with well-known provider partnerships and enhanced production procedures.

Exactly how Does the Surface Complete Affect Light Weight Aluminum Casting Efficiency?

The surface coating markedly impacts aluminum spreading efficiency by affecting deterioration resistance, aesthetic quality, and rubbing features. A smoother finish enhances resilience and functionality, while a rougher structure can improve attachment for subsequent coverings or therapies.

Several materials are utilized in manufacturing, light weight aluminum spreadings stand out primarily due to their light-weight buildings. When revealed to air, aluminum reacts to form a slim, protective layer of light weight aluminum oxide. Cost-effectiveness in aluminum spreading production is primarily attained through decreased product waste and efficient production processes. Decreasing product waste in aluminum casting procedures substantially improves production efficiency. Eventually, effective use of raw products enhances the affordable setting of companies in the market, making light weight aluminum spreadings a favorable choice in numerous applications.